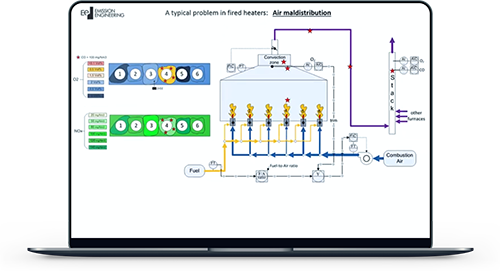

Furnace optimizing tool

EVEN is a measuring tool that allows operators of fired heaters to not only measure the air distribution to all burners, but also to correct them and measure the results in real time. This leads to more uniform heat input as excess air on each burner is similar and furthermore the O2 measurement (normally located as a spot measurement at the bridgewall and of ZrO2 type) becomes more representative for the overall average O2 content across the entire flue gas duct.

Advantages:

- Easy and quickly to install: no furnace shut down needed. Installation time depending on the N° of burners per heater but typically one or max. two days.

- High acceptance: it can be understood very easily as simple to read and straight forward in the way operators need to act

- Safer operation: fuel / air ratio can now be determined and adjusted as per design excess air and within the parameter given in API 535, API 560 and DIN EN 746-2 (although those norms don’t tell how to achieve it – now with EeEVEN you can).

- Low-budget: price depending on the N° and type of burners but far below compared to other concepts

- Oversized burners: can be detected instantly. (Oversizing is very often a key problem, when trying to lower excess air to its design values)

- Available for installation in non-explosive or explosive (ATEX) area

Requirements:

Burners with constant air side pressure drop design over time

Typical furnaces:

(but not limited to)

Crude oil destillation

Vacuum destillation

Coker

Platformer

Visbreaker

not usable for:

self inspirating premix burners (e.g.

radiant wall burners on ethylene or EDC cracking furnaces)

Proceed here to our product videos:

EVEN – the ultimate furnace optimizing tool

SMART-DRAFT – The draft attenuator

and more interesting videos for example those of our serie:

“The Art of Furnace Operation”

Just type in your email address and you are automatically forwarded to see our videos. By depressing the button “GO” you agree that the entered email address will be saved in compliance with the current data protection guidelines.

This video was elaborated for you free of charge. We trust that you play fair by inserting your real and correct email adress. Thanks.